Introduction

The term “supply chain” refers to the various organizations and people engaged in the production and distribution of a good or service.

Supply chains start with the producers who generate the raw materials and end with the person who receives the finished product from a delivery medium.

Production facilities, suppliers, storage facilities, logistics providers, distribution hubs, and retail outlets form a core component of the supply chain.

The most vital functions associated with the supply chains include product research and development, marketing and promotion, management and administration, distribution, financing, and customer support.

If you are looking to build a career in this domain, supply chain management is the most crucial concept to master. It trains you on how to optimize and streamline supply chain processes, irrespective of the industry.

The primary objective of supply chain management is centralizing supply chain activities to ensure they are carried out in the most cost-effective and operationally efficient manner possible from the initial stage to the end.

It involves everything from product ideation to development and management, in addition to the methodologies, systems, and technologies employed to guide these operations.

So, let’s delve deeper into the supply chain and explore the various strategies and models that come into implementation, ensuring the smooth running of operations across industries.

Four Crucial Types of Supply Chain Strategies

Even if you have a flawless supply chain model in place and the most cutting-edge tools available, you might run into trouble if you don’t have a solid supply chain strategy deployed.

So, let’s understand the prominent supply chain strategies that serve distinct purposes but have proven to be instrumental in eradicating inefficiencies from the process:

- Client-Centricity: Plan and Deliver for the Segment of One

Client centricity must be synchronized with segment-specific digital supply chain functionalities in today’s digital landscape.

The process begins with an automated supply chain managed on an exception basis. By using this strategy, supply chain professionals can offer their complete attention to customer-centric, value-adding tasks.

A precise snapshot of actual demand is necessary for this degree of automation to serve you well. Improving the reliability of forecasts is still crucial but not sufficient. Demand signals from diverse data sources need to be captured in real-time.

While unstructured data comes from sources like emails, social networking platforms, prediction models and algorithms, sentiment analysis, etc., structured data comes from point-of-sale systems, order placement systems, and IoT sensors.

Integrating this data will paint a more accurate picture of demand, which can provide valuable insights to serve customers better and boost overall profitability and performance.

To satisfy this demand, businesses must adopt integrated planning methods that can adapt to fluctuations in supply, demand, and other supply chain indicators in real time.

Companies can now easily manage their partner groups, collaborate with them, and execute shipments of any size, from a single item to numerous truckloads crossing international boundaries, all thanks to this streamlined supply chain logistics process.

It allows businesses to satisfy their customers’ needs regardless of how rapidly the demands, priorities, and technology are transforming.

- Predictive Business: Plan, Make, and Maintain the Product of One

Establishing and maintaining digital twin networks is state-of-the-art for predictive businesses.

A digital twin entails connecting a real-world asset or product with its digital counterpart throughout its lifecycle using the data collected by Internet of Things (IoT) sensors.

Leveraging digital twins, you can get a bird’s-eye view of your whole system and all the equipment, resources, and products inside it, including those in customers’ residences and entire installations of commercial-grade assets in the field, as well as those in your own facility.

Nonetheless, you must utilize the available data to generate genuine product and asset insight and then execute it.

The greater your understanding of how products function and are utilized, the more precisely you can predict service interruptions and determine what consumers desire most.

By gathering and combining client demand and usage information throughout a chain of resources and services embodied by a digital twin, it is possible to gain actionable insight into the future.

This advantage can result in more relevant product design and development, better customer service, and greater field availability with market impacts.

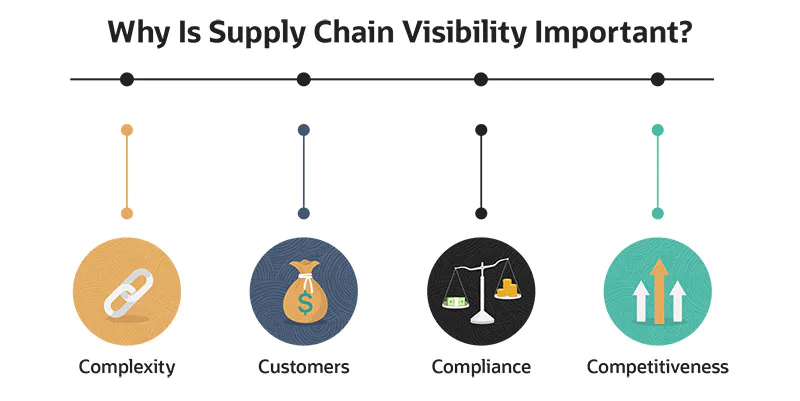

- Total Visibility: Examine and Manage the Supply Chain of One

A digital reflection of your organization is typically required for total supply chain visibility.

The goal is to monitor every aspect of the supply chains, from raw materials to finished products to market demand indicators and data from sentiment analysis, POS systems, and beyond.

To have complete visibility means to be aware of all factors that may affect sales and delivery, such as traffic, accidents, and weather conditions.

You must be able to adapt your ways of collaborating and coordinating across complex business ecosystems of partners, warehouses, production facilities, and fulfillment centers.

A modern supply chain process always surpasses the confines of a single firm’s constraints. You may bridge the gap between the real world and the envisioned one with a digitized reflection of your enlarged supply chain.

The goal is to be able to anticipate and respond to demand spikes and disruptions.

If you can master this skill, you can reduce vulnerabilities throughout the supply chain, increase your company’s adaptability, and provide customers with what they really want: a satisfying experience and satisfying results.

- Smart automation: Ensure You Manufacture the Lot Size of One

From self-driving forklifts and robotic warehouse operations to the prospective use of unmanned aerial vehicles to deliver goods, automation is pervasive across both inbound and outbound supply chain logistics.

However, the shift from mass-scale manufacturing to product personalization and customization has propelled the industrial sector to the forefront of smart automation.

Some of the most successful businesses today are reevaluating their production, design, and distribution channels to take advantage of this opportunity.

The shift from static production lines to mobile, plug-and-play cells is a major development in the manufacturing sector. By providing vital status information, smart sensors facilitate the automated routing of goods to the subsequent cells in the production chain.

Organizations may more easily produce the lost volumes of one required by the market for customized goods. Companies are not just reconfiguring their production techniques to become more flexible but also their logistics and delivery systems.

Once considered a liability, modern companies recognize the strategic value of fulfillment centers as a source of competitive edge. This advantage is becoming a reality for businesses thanks to numerous powerful modern technologies.

Many businesses are adopting 3D printing to make things on demand, for instance, to increase adaptability without the high cost of maintaining a huge inventory.

The Internet of Things (IoT), robotics process automation (RPA), and ML capabilities are all adopted by businesses across industries.

You can also enroll in Hero Vired’s Strategic Management and Business Essentials in collaboration with INSEAD program to get your supply chain certification and learn about these strategies more holistically.

POSTGRADUATE PROGRAM IN

Financial Analysis, Valuation, & Risk Management

Learn financial modeling, valuation techniques, and risk management to drive strategic business decisions.

Four Key Types of Supply Chain Models

There are four distinct supply chain models to select from, each tailored to a different set of business industries and objectives:

- Integrated Make-to-Stock Model

This model keeps tabs on real-time consumer demand to facilitate timely processing and replenishment of finished product inventories.

Businesses can benefit from real-time demand data that can be harnessed to revise production plans and schedules with the help of a completely integrated enterprise resources planning (ERP) system.

Then, the procurement department receives this updated information from the supply chain.

For instance, a video game business may manufacture millions of gaming console units without waiting for buyers to express interest since they already know there will be a market for their products based on their past sales performances and demand projections.

- Build-to-Order Model

This supply chain model centers manufacturing around meeting consumer demand. This approach can be applied to a supply chain spanning multiple locations and production lines and necessitates monitoring inventory and delivery systems effectively.

The idea of mass customization gets strengthened by this supply chain model, which gives the impression to customers that they are getting products tailored to their specific needs in a timely fashion.

- Continuous Replenishment Model

This model emphasizes maintaining a steady inventory of goods by regularly informing suppliers of actual sales or warehousing shipments.

As an example, the supply of prescription pharmaceuticals is a good setting for this model because of the remarkably consistent demand they experience.

- Channel Assembly Model

The channel assembly supply chain model is essentially the build-to-order model with a few tweaks.

The product is assembled from its components as it passes through the distribution chain. In most cases, it is accomplished through partnerships with third-party logistics providers (3PL).

Conclusion

Proven supply chain management strategies and specialist models allow businesses to seamlessly achieve a lean supply chain in today’s era of digitization.

They can overcome shortcomings, cut costs, eliminate inefficiencies in the system, streamline inventory tracking, facilitate cross-border transactions, and boost sustainability and compliance across the worldwide supply.

It is also important to remember that the relevant supply chain strategies, models, and tools can only be acquired and implemented after a thorough assessment of the business demands above all.

That is where a comprehensive supply chain course certification from Hero Vired can help you stand out in front of companies hunting for supply chain management talent.