Introduction

Supply chain management (SCM) refers to the process of administering the flow of goods and services along with transforming the raw materials into finished commodities.

It encompasses a comprehensive methodology through which a company actively streamlines its supply-side operations to optimize customer value and achieve a competitive edge.

The primary objective is to coordinate the efforts of a company’s suppliers to design and operate a supply chain that maximizes efficiency and cost savings.

By implementing effective SCM strategies, you can integrate the entire supply chain across the procurement, manufacturing, transport, and distribution stages of a product’s lifecycle.

Managing the many individuals, operations, data, and technologies that contribute to making a supply chain function a smoothly running machine is no easy endeavor.

Effective SCM necessitates a high-level, strategic perspective and the competence to zero in on the specific methods and systems causing bottlenecks.

This is where the need for employing SCM experts arises, opening a door of opportunities for people skilled in the domain.

So, here is an all-inclusive guide on supply chain management to give you a bird’s eye view of how a supply chain works seamlessly from product sourcing till the customer receives the finished product at their doorstep and, oftentimes, back to the warehouse.

Also Read: Supply Chain Management Interview Questions

Get curriculum highlights, career paths, industry insights and accelerate your finance journey.

Download brochure

What are the Key Benefits of an Effective Supply Chain Management Process?

-

Better Efficiency Across the Supply Chain

Companies find themselves better positioned to anticipate demand and meet customer needs when their supply chain practices, which include resource procurement, logistics, and delivery, are well-planned and executed.

Therefore, an organization’s agility to respond to upheavals, emerging markets, and evolving industry trends gets boosted significantly.

-

Greater Cost-Efficiency

Inventory management is a part of SCM that can lead to additional savings when well-designed and implemented.

Leveraging technology, firms can gain insights into order volume, popular products and services, and stock information, thus preparing to fulfill customer demand and expectations.

As a result, you will be in a healthier position to control expenses and allocate resources judiciously.

-

Helps Foster Relationships

An essential part of global supply chain management is developing mutually beneficial partnerships with distributors and vendors.

Increased productivity and significant cost reductions can result from fostering vital partnerships with suppliers via constant communication and collaborative problem-solving.

Distribution inefficiencies, logistical problems, and shipping delays all get mitigated as a direct consequence.

In addition, the latest software solutions and metrics for measuring performance give businesses the tools they need to make informed vendor and supplier selections.

Their potential contribution to your supply chain is based on their pricing model, quality assurance procedures, and delivery times.

-

Enhances the Business Cash-Flow

Increased customer satisfaction levels and more efficient invoicing procedures are the direct results of a streamlined supply chain.

It not only brings down the company’s overhead expenses but also improves its cash flow, making it much smoother to run its day-to-day business. This way, the business can witness better growth prospects and productivity levels.

-

Minimizes Regulatory Liabilities

Companies capable of effectively supervising their supply chains are better placed to avoid the reputational damage and legal penalties that can arise from failing to adhere to global CSR regulations.

When companies have insightful, actionable data about potential risks, they can prepare themselves to reduce the liabilities that come with the risks.

This could be done through any defensive strategy, such as purchasing new insurance plans, upgrading resources, implementing new technologies, or improving work procedures.

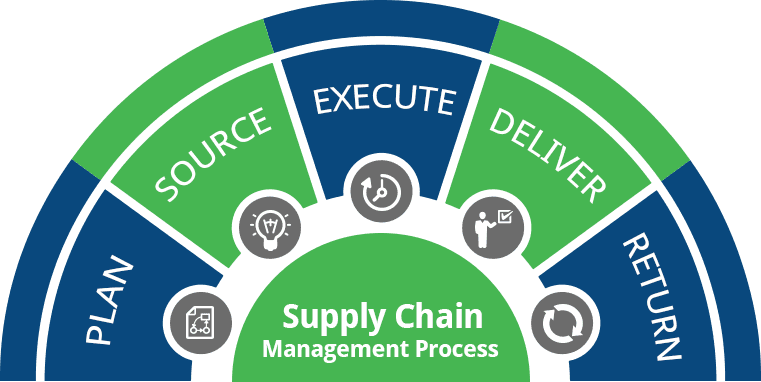

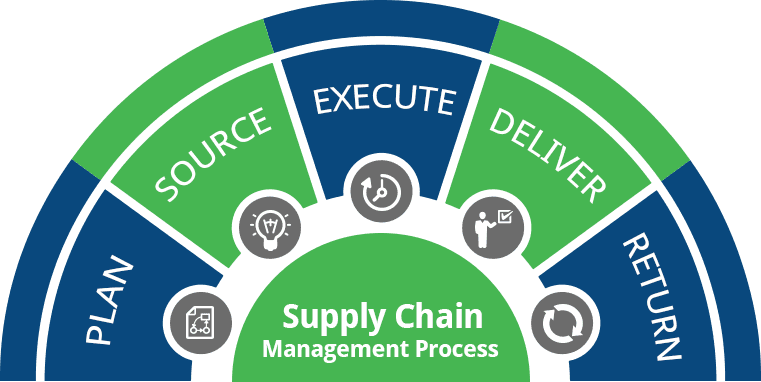

Five Stages of the Supply Chain Management Process

Let us delve deeper into the five vital components of the supply chain that will help you understand the SCM process inside out.

-

Plan

Planning to align supplies with consumer and production expectations is typically the first step in SCM processes that yield the best outcomes.

To succeed, businesses need to look ahead to their future requirements and plan accordingly. This concerns the availability and quantity of raw materials, the capabilities and constraints of necessary equipment, and the number of workers required at various points in the SCM process.

-

Source

In a production setting, sourcing implies coordinating with third-party suppliers to obtain all necessary raw materials.

A business can potentially save time and money by working ahead of time with a supplier to procure needed supplies. However, sourcing demands can vary widely between sectors. SCM sourcing typically entails checking off these boxes:

- All required raw materials are available and satisfy the manufacturing specifications.

- The cost paid for the commodities are reasonable in comparison to market consensus.

- The provider can deliver emergency supplies even if there are unforeseen situations.

- The supplier has a reputation for delivering goods on schedule and in satisfactory condition.

-

Make

The core of the business’s supply chain management process is the transformation of raw materials by means of machinery, workforce, or other external factors.

Phases like assembling, testing, examination, and packaging are encompassed in the manufacturing process. During production, companies need to keep in mind the potential for waste or other variable elements that may deviate from their initial blueprints.

-

Deliver

Once production is accomplished and sales orders get confirmed, a business must ensure that the customers receive their orders.

For a successful SCM process, the company needs reliable logistical support and efficient distribution channels to ship items on time, in the best condition, and at a reasonable cost.

This includes having alternative distribution channels available in case a primary one becomes temporarily unavailable.

-

Return

Product and customer return assistance is the final step in the SCM process. The business must make sure it can accept returned products and properly allocate refunds for such returns; a process known as reverse logistics.

Whatever the reason for the transactional repayments, whether it be a product recall or dissatisfaction on the part of the customer, it must get fulfilled speedily.

Consider enrolling in an online supply chain management course if you want a more in-depth understanding of these phases of the SCM process.

Understanding Modern Supply Chain Management Through the Amazon Model

Today, with innovation dictating the terms in this century, supply chains have not been left untouched. Let us take the real-world example of Amazon and understand how the eCommerce giant has innovated both supplier-side and delivery-side supply chain links.

Amazon hosts all product consumers need in everyday life. It sources popular products at low cost and undercuts competitors by placing bulk purchasing orders.

Secondly, their fulfillment centers heavily leverage automation to group products bound for similar destinations together, making them readily available for delivery.

Finally, the company has invested in its delivery crew and technology to the point where same-day and two-day shipments are the norm rather than the exception.

Amazon no longer relies on third-party logistics (3PL) and instead handles all aspects of order fulfillment in-house.

What is the Role of Supply Chain Management Software in the Overall Process?

An SCM software is a tool that assists keep track of every activity that goes on in a company’s supply chain. Its applications span the supply chain and include logistics and distribution, quality control and management, and the administration of suppliers.

So, if your supply chain is becoming increasingly complicated, investing in supply chain management software can help you get greater insights into your operations and gain better control over them, all while increasing productivity and bolstering your resilience to disruption.

Nowadays, you can deploy low-code process apps that can improve SCM by connecting to preexisting networks and adding a layer of operational flexibility on top of ERP and similar technologies.

Some top-quality supply chain management courses available online can provide you with hands-on training on SCM tools, which you can showcase to land a lucrative job in SCM.

Top 5 Career Opportunities in the Supply Chain Management Domain

After obtaining holistic supply chain management training, you can consider starting a new career in any of the following prominent SCM roles:

-

Supply Chain Manager

A manufacturer’s success is directly tied to the efforts of the supply chain manager.

Supply chain managers, or SCMs, impact their companies by contributing their experience and expertise to developing strategies that improve safety, effectiveness, and profitability from the moment a company commences the new product development process until the finished product is shipped.

The annual salary of a Supply Chain Manager ranges between ₹3.0 Lakhs to ₹27.7 Lakhs, with an average of ₹10.0 Lakhs.

-

Strategic Planner

A strategic planner’s job includes formulating long-term plans for the success of large and medium-sized businesses.

The Strategic Planner is responsible for providing strategic advice to upper management after being well-versed in all facets of the company’s operations.

The annual salary of a Strategic Planner ranges between ₹5.7 Lakhs to ₹34.5 Lakhs, with an average of ₹12.0 Lakhs.

-

Purchase Manager

Managers in this position are responsible for sourcing products and services at the most competitive prices for resale or internal use by the business. Managers of purchasing departments have different tasks in different fields.

The annual salary of a Purchase Manager ranges between ₹3 Lakhs to ₹18.5 Lakhs, with an average of ₹7.0 Lakhs.

-

Warehousing Manager

Warehouse Managers ensure the smooth inflow and outflow of goods, as well as their safekeeping and subsequent shipment.

To ensure that items are collected and sent out properly and that performance objectives are met, they are responsible for managing people, procedures, and systems.

The annual salary of a Warehouse Manager ranges between ₹2.4 Lakhs to ₹13.0 Lakhs, with an average of ₹4.8 Lakhs.

-

Materials Analyst

The job of a company’s Materials Analyst is to maintain a streamlined flow of goods through the distribution channels.

A Materials Analyst has a wide range of responsibilities inside an organization. In this role, they make sure that a business has enough supplies on hand to complete any future projects that may be planned. Each year, they devise strategies for how the business can most efficiently source its raw materials.

The annual salary of a Materials Analyst ranges between ₹2 Lakhs to ₹14.0 Lakhs, with an average of ₹5.5 Lakhs.

Conclusion

Managing a supply chain involves a diverse range of tasks and operations and is a multi-dimensional undertaking.

Organizations need to create and sustain a robust supply chain by having a firm grasp on the various tiers of supply chain and logistics management and the interdependencies among their components.

That is why the demand for skilled and talented managers in the domain is on the surge. An extensive supply chain management certification like Hero Vired’s Certificate Program in Strategic Management and Business Essentials can be your answer to prepare for landing a reputed job in this industry.

Completing the course can help you stand out in front of companies hunting for supply chain management talent. So, start now!

FAQs

Updated on February 10, 2025