The Process Control Block (PCB) is a crucial data structure used by the operating system to manage and track information about processes. It contains essential data like registers, quantum, and priority, enabling efficient process management. The process table, an array of PCBs, holds entries for all current processes in the system. The PCB plays a central role in ensuring the OS functions smoothly by effectively handling process-related tasks.

What is the Process Control Block(PCB) in OS?

The PCB contains key details such as the process’s current status, program counter, memory usage, open files, and CPU scheduling information. This structure allows the OS to manage and schedule processes properly, playing a vital role in the efficient use of memory and system resources. Without the PCB, the operating system would be blind to the processes it governs, making it indispensable for smooth OS functionality.

When a process is created, the operating system generates a PCB to store all the details required for process management. This PCB holds information about the process’s state and behavior, allowing the system to track the progress of the process and allocate resources accordingly. In turn, the OS relies on these PCBs to actively monitor processes and run them efficiently. The creation of a PCB for each process is done with the purpose of helping the OS manage the large number of tasks being executed. The PCB stores all pertinent information, including the process’s current status, program counter, memory use, open files, and other crucial data. All this information is essential for the OS to manage and control processes effectively.

PCBs are fundamental in allowing the operating system to monitor processes, manage system resources, and regulate execution. By using PCBs, the OS is able to optimize its performance, efficiently schedule processes, and maintain system stability.

Also read: Process in Operating System

POSTGRADUATE PROGRAM IN

Multi Cloud Architecture & DevOps

Master cloud architecture, DevOps practices, and automation to build scalable, resilient systems.

Structure of the Process Control Block

1. Process ID:

Each process is assigned a unique ID (Process ID) when created. The IDs range from 0 to N-1 (depending on the system limit). IDs are assigned either in ascending order or by reusing IDs from terminated processes. Each process ID corresponds to a slot in the PCB, with memory reserved for all potential PCBs.

2. Process State:

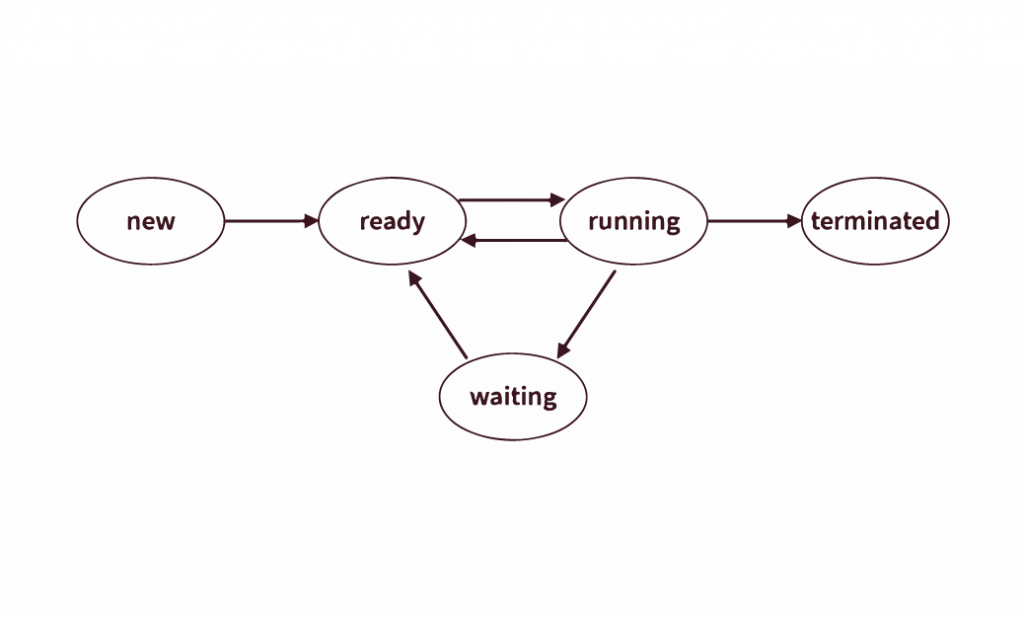

A process transitions through several states:

- New: Process ready to be loaded into memory.

- Ready: Loaded into main memory, waiting for the CPU.

- Running: Actively being executed by the CPU.

- Blocked/Waiting: Paused, awaiting an event or resource.

- Terminated: Process has completed execution and its PCB is deleted.

3. Process Priority:

Each process is assigned a numeric priority (lower value means higher priority). This priority is set at the time of PCB creation and can be influenced by factors like resource consumption or user input.

4. Process Accounting Information:

This tracks the resources consumed by a process during its lifetime, including CPU time and connection time.

5. Program Counter:

Points to the next instruction to be executed in the process, helping the system track its current position in execution.

6. CPU Registers:

These are small, fast storage locations in the CPU used to store temporary data for rapid access during execution.

7. PCB Pointer:

Holds the address of the next PCB in the ready state, helping the OS manage process hierarchies and transitions.

8. List of Open Files:

Tracks all files currently opened by the process, ensuring the OS can manage them, especially at termination.

9. Process I/O Information:

Lists all input/output devices needed by the process during execution, ensuring smooth resource allocation.

Understanding Operations Handled by the PCB in OS

- Process Schedule: The OS can arrange the process in the execution stack using various data, such as process priority, process state, and resources consumed. In order to determine when the procedure will be carried out, the scheduler looks up the priority and other details.

- Multitasking: The OS can multitask and run multiple processes at once with the help of resource allocation, scheduling, and process synchronization.

- Context Switching: The process state is preserved in the CPU register and a copy is stored in the PCB when the OS switches contexts. The CPU retrieves that value from the PCB and returns the process to its initial state when it transitions from one process to another and back again.

- Sharing Resources: The PCB keeps track of resources that a process is utilizing, including memory allotted and open files. This information aids the operating system in allowing a new process to share resources with any other process that may be using them.

Optimizing Process Scheduling through Process Control Block in OS

In operating systems that support multitasking, process scheduling controls how processes share and use the central processing unit (CPU). This guarantees fairness and optimal system performance through effective CPU allocation. The Process Control Block, or PCB in OS, is the key component of this scheduling method.

Important details on each PCB in the operating system, such as its state, priority, and CPU burst time, are stored by the OS. The scheduler looks up these details in the PCB in the OS while determining which process to execute next. Moreover, a process’s current state is preserved to its PCB during context switches, facilitating seamless transitions and process resumes. As a point of reference and storage for the OS, the PCB essentially supports the full process scheduling function.

82.9%

of professionals don't believe their degree can help them get ahead at work.

Advantages and Disadvantages of PCB

Advantages of Process Control Block (PCB)

- Efficient Process Management: The Process Control Block allows the operating system to manage multiple processes that ensures maximum resource utilization.

- Quick Context Switching: In order to keep the system responsive the PCB allows rapid context switching by storing the state of a process.

- Resource Tracking and Allocation: The PCB tracks all the resources allocated to a process to make sure that the resources are used effectively and the errors are minimized.

- Simplified Process Control: The PCB provides a centralized structure for storing process information, simplifying the control and management of processes within the operating system.

Disadvantages of Process Control Block (PCB)

- Increased Overhead: When there are a large number of processes, maintaining them can create major overheads which consumes memory and processing power.

- Synchronization Issues: For ensuring that the PCBs are updated correctly and consistently with multi-threads, complicated synchronization mechanisms are required.

- Difficulty in Modifications: Once a PCB structure is created making changes or updates can be complex and may require significant redesign efforts.

Advancements and Future Prospects of Process Control Block in OS

The Process Control Block (PCB) in operating systems has always been a cornerstone for effective process management. Looking ahead, we can foresee:

- Enhanced Structures: As processes grow in complexity, the PCB in OS is likely to evolve, incorporating additional data fields to improve process monitoring and control.

- Optimized for Speed: With the rise of faster CPUs and advanced memory technologies, future PCB designs may be fine-tuned for quicker context switching and minimized overhead.

- Improved Resource Management: Future PCBs might include more refined resource management capabilities, ensuring efficient allocation and utilization of system resources.

The Storage Structure of Process Control Blocks in OS

The operating system typically maintains Process Control Blocks (PCBs) as data structures in memory. Here are some common approaches:

- Array of PCBs: Each element in the array represents a different process, with its index serving as its unique identifier. This method uses the process ID as an index, allowing for quick access to a PCB.

- Linked Lists: Linked lists can be utilized to organize PCBs. Each element in the list represents a PCB for a specific process, enabling dynamic management of processes.

- Tree Structures: In systems with complex process hierarchies (parent-child relationships), tree structures can be employed to illustrate the connections between processes. The tree structure builds the parent-child relationships, with each node in the tree containing a PCB.

- Hash Tables: For systems with a large number of processes, a hash table can be used to store PCBs. The process ID is hashed to generate a table index, and the entry at that index stores the PCB, facilitating efficient retrieval.

- Circular Queues: In this approach, PCBs are stored in a circular queue, which can be particularly useful for round-robin scheduling. This ensures that the scheduler can easily cycle through processes in a circular manner.

- Stacks: For certain types of process management, such as handling nested interrupts or recursive processes, PCBs can be stored in a stack. This allows for last-in, first-out (LIFO) access, which is suitable for these scenarios.

Conclusion

The Process Control Block in Operating Systems is a crucial component that helps in managing and executing processes efficiently. PCBs store critical information about each process, such as process ID, state, priority, CPU registers, and more. While PCBs offer numerous advantages such as efficient process management, multiprogramming, and fast context switching, they also have some limitations such as increased overhead and the need for careful synchronization.

What is a Process Control Block?

Why is the Process Control Block important in an operating system?

Can the information in a PCB be modified during process execution?

What role does the PCB play in memory management?

How does the PCB contribute to process scheduling?

Updated on October 10, 2024